Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Produktbeschreibung

Produkteigenschaften

Modell: MGN

Marke: Wkt

Status: Neu

Garantiezeit: 1,5 Jahre

Anwendbare Industrie: Produktionsstätte, Bauarbeiten

Service Außerhalb Der Garantie: Online-Hilfe, Wartung und Reparatur vor Ort

Wo Können Lokale Dienstleistungen Erbracht Werden (in Welchen Ländern Gibt Es Servicestellen In Übersee)?: Truthahn, Spanien, Kirgisistan

Ausstellungsraum (in Welchen Ländern Gibt Es Musterräume In Übersee): Kanada, Russland, Japan

Inspektion Der Videofabrik: Unter der Voraussetzung

Mechanischer Prüfbericht: Unter der Voraussetzung

Marketing-Typ: Neues Produkt 2020

Garantiezeit Für Kernkomponenten: 1 Jahr

Kernkomponenten: Motor, Getriebe

Herkunftsort: China

Lieferfähigkeit & Zusatzinformationen

Verpakung: Holzpaket oder Cartoon

Produktivität: 2000pcs/month

Transport: Ocean,Land,Air,Express

Ort Von Zukunft: Suzhou.

Unterstützung über: 2000pcs/month

Zertifikate : IATF16949

Hafen: ShangHai

Zahlungsart: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,Express Delivery,CFR,CIF,EXW,FAS,FCA,CPT

Produktbeschreibung

MGN type miniature linear guideways

Spezifikation :

The new RG series from Hiwin features a roller as the rolling element instead of steel balls. The roller series offers super high rigidity and very high load capacities. The RG series is designed with a 45-degree angle of contact. Elastic deformation of the linear contact surface, during load, is greatly reduced thereby offering greater rigidity and higher load capacities in all 4 load directions.The RG series linear guideway offers high performance for high-precision manufacturing and achieving longer service life.

Rolling circulation system: Block , Rail , End cap , Circulation path, rollers

Lubrication system: Grease nipple and piping joint

Dust protection system: End seal, Bottom seal, Cap, Double seals and scraper

Hauptmerkmale :

1.Built-in long life lubrication

2.High positional accuracy

3.High speed motion is possible with a low driving force

4.Equal loading capacity in all directions

5.Easy installation

6.Inter change ability

Vorteile :

(1) Optimal design

fEM analysis was performed to determine the optimal structure of the block and the rail. The unique design of the circulation path allows the RG series linear guideway to offer smoother linear motion.

(2) Super high rigidity

The RG series is a type of linear guideway that uses rollers as the rolling elements. Rollers have a greater contact area than balls so that the roller guideway features higher load capacity and greater rigidity.

(3) Super high load capacity

With the four rows of rollers arranged at a contact angle of 45-degrees, the RG series linear guideway has equal load ratings in the radial, reverse radial and lateral directions. The RG series has a higher load capacity in a smaller size than conventional, ball-type linear guideways.

(4) Operating life increased

Compare with the ball element, the contact pressure of rolling element is distributed on the line region. Therefore, stress concentration was reduced siginificantly and the RG series offers longer running life. The nominal life of RG series can be calculated by using Eq.

1. We Screwtech is a professional manufacturer of Ball Screws,Lead Screws.Meanwhile, Distributing Stepper Motor,Linear Guideway,AKD-Support for ball screw,Coupling,Linear Module for more than 10 years.

2. We are factory:We can offer you products of high quality with competitive price.

3. Customized service:Various models are available upon request.

Automation Device ; Transportation equipment ;CNC machining centers; Heavy duty cutting machines ; CNC grinding machines; Injection molding machines ; Electric Discharge Machines ; Plano millers; Devices requiring high rigidity and high load capacity.

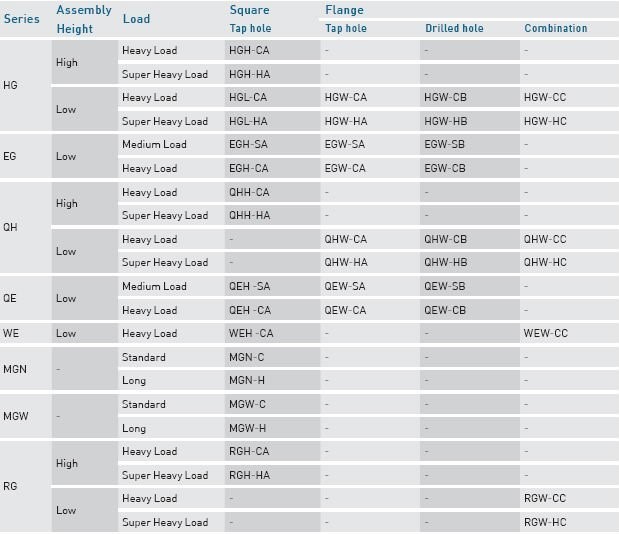

HIWIN linear guide models:

1.BALL SCREW

SFU SERIES,SFE SERIES,M-ISNF SERIES,M-ISNA SERIES,M-CSNF SERIES BALL SCREW

2. LEAD SCREW

3. LINEAR MODULE

4.FLEXIBLE AND RIGID COUPLING

5.STEPPER MOTOR

6.SUPPORT UNIT

heiße Produkte

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.